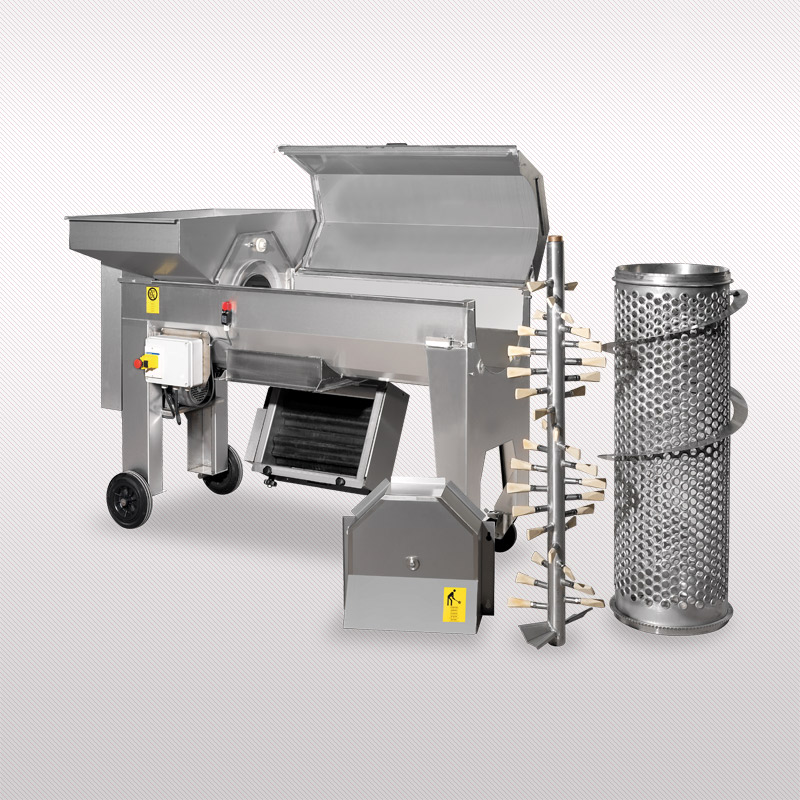

These machines are indicated for the wine, for the production of juices and are widely used in the processing of citrus fruit. The machines are built in stainless steel (structural parts, propellers, cage, draining sheets and covers) VERSION S – with opening head and removable cage, access to internal parts for cleaning. Suitable for the chemical and food industries. Available in ATEX and electropolished.

Data sheet

bielica modelli_model 10 20 40 50 70 150

GENERAL FEATURES

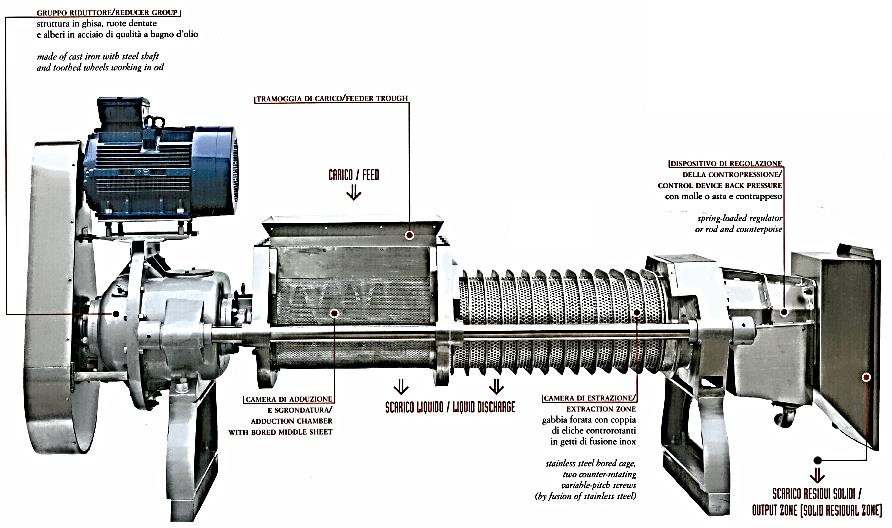

The pressing process is enhanced by the variation of the diameter of the two counter-rotating propellers: greater, in the first zone, the lower, in the pressure zone. In this manner is obtained, during the transport of the product inside the machine action, a volume change of the quantity contained in one step. The variable pitch propellers ensure, also, a constant increase of the action of pressing. The low propeller rotation speed ensure a gradual and continuous pressing and an excellent volumetric efficiency. When used to fade the MP series machines are provided with suitable tapering of propellers and with a high surface finish (to ensure less friction with the product). The MP can be equipped with a dispenser for furnish process water to the pressure zone. This procedure is useful in blending operations. A control system specially designed allows you to adjust the machine depending on the product features and the required degree of pressing. The already simple cleanup procedure of MP series extractors is further simplified in version S models, in which the opening of the terminal head, mounted on vertical hinges, allows the removal of the pressure cage without unscrewing a single screw. A wide range of models allows to meet the specific needs of potential.

Modelli disponibili

accordion

Italiano

Italiano