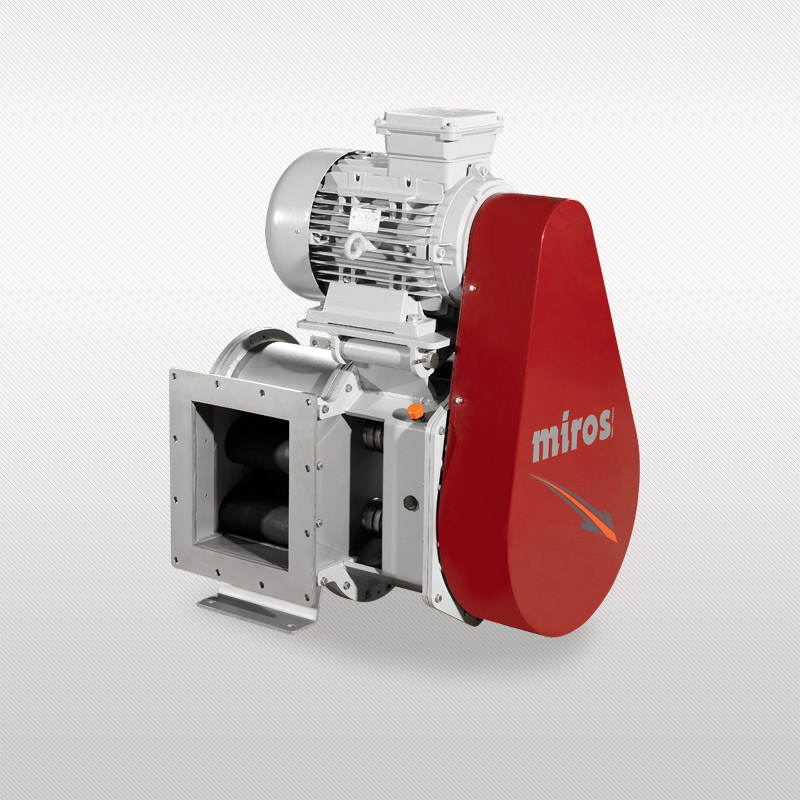

The compact size allows direct flange mounting with screw and conveyors, saving trays and hoppers, also the version with trolley is naturally available, with its feed hopper (optional).

This machine is designed in a symmetrical manner so you can reverse the feeding input without mechanical problems.

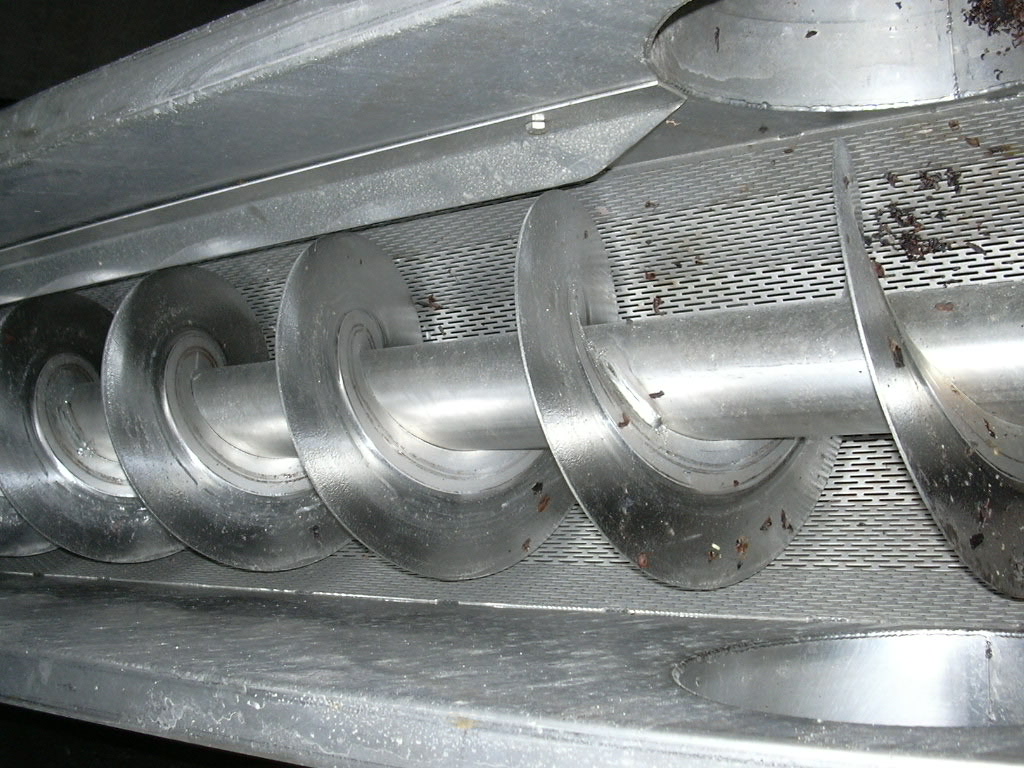

The flow is constant once the number of revolutions of the wheels fixed. in these pumps it exploits the volume change caused by the gear between the petals of the rollers.

Cleaning is very simple and is carried out by passing water inside the pipe. The residues are then discharged through a special valve on the discharge flange.

Any replacement of the lobes is quick and easy, you will only dismantle the wall and remove the rollers with special guides.

Technical features

- Non-toxic rubber rollers with three petals mounted on parallel shafts

- Supports sealed Widia / Widia

- Reduction unit molded in pump frame

- Body built totally in stainless steel

- Pump discharge through the valve (optional)

- Inspection of suction side through hand

- Pump waste discharge through the valve in the exhaust side

- Roller security through shear pin

Data sheet

PDF LOBE PUMP PLM_Description

Italiano

Italiano