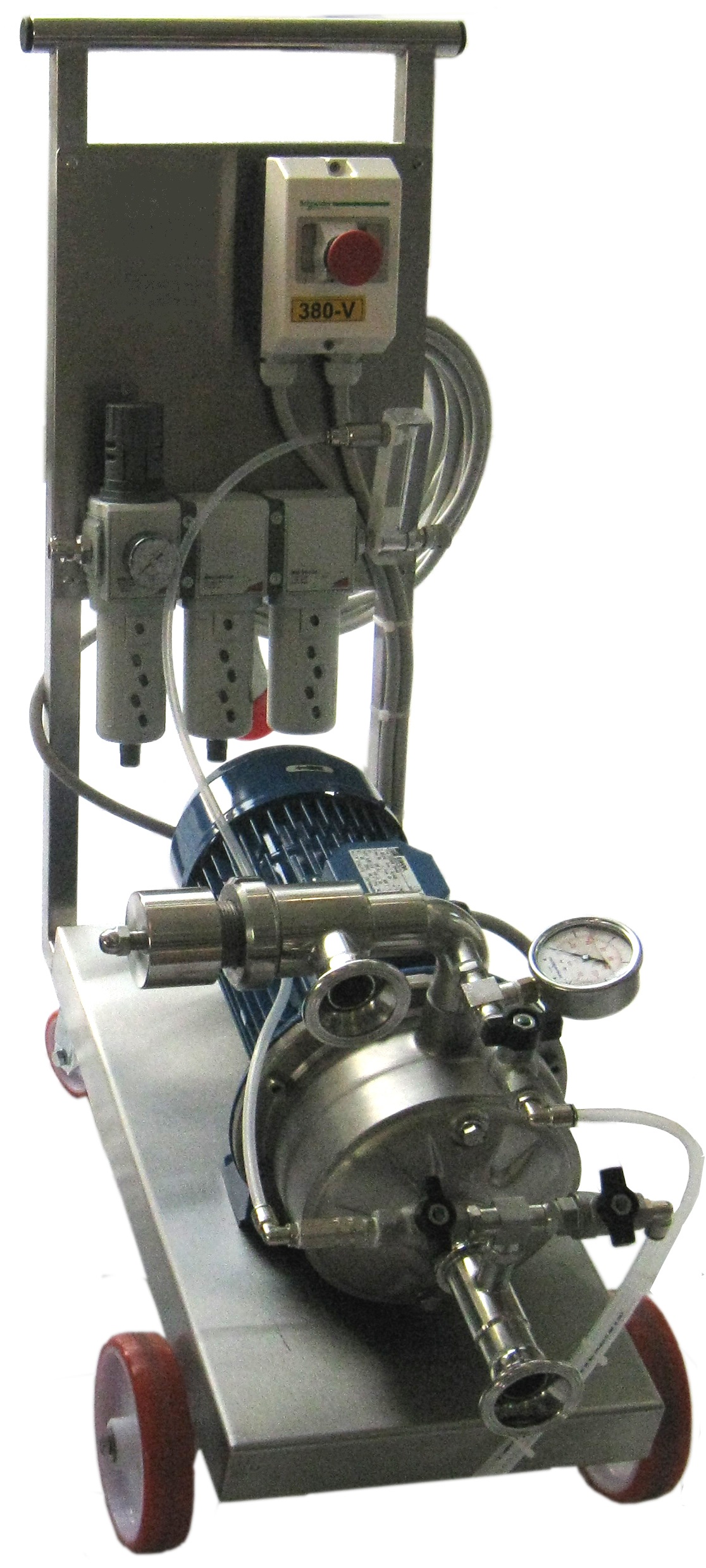

The eccentric screw pumps (also called progressive cavity or mono) are constituted by a stator in elastic material (usually synthetic rubber) inside of which is imprinted a spiral, and by a usually metallic rotor in a spiral shape, of a diameter lower than the imprint of the stator, eccentric with respect to the axis of rotation.

The two spirals are made so that there are always generatrices in contact, and thus creating a sealed cavity (thanks to the contact metal rotor – stator rubber) that moves thanks to the eccentric rotational movement, towards the delivery opening. These pumps are very versatile, and withstand liquids with suspended solids, if not too abrasive; They are suitable for low to medium flow rates and prevalence medium and medium-high. thanks to their longitudinal development, have low bulk and are suitable to be introduced to the discharge of the tanks to effect emptying.

Data sheet

PDF ECCENTRIC SPIRAL PUMP (MONO)_Description ECCENTRIC SPIRAL PUMP (MONO)_Dimensions

Italiano

Italiano